Nanocoating & Nanoclear® Stencil Treatment

WINNER 2014 Circuits Assembly New Product Introduction Award & WINNER 2014 Global Technology Awards

Proven technology in PCB assembly for over 5 years

NanoClear wipes:

- Modify stencil contact surfaces with a flux repellent nanocoating in minutes

- Increase yields and output on SMT assembly lines

- Improve print quality and reduce variation

- Decrease understencil wipe frequency

- Utilize proprietary SAMP technology

- Surpass competitive coatings in cost, performance and ease of us

Overview of Print Quality Improvements

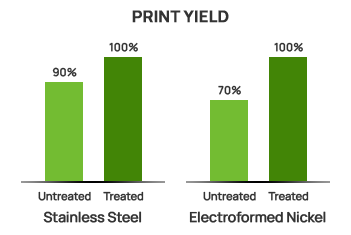

Higher Print Yields

Effective on all stencil materials

Effective on all stencil materials

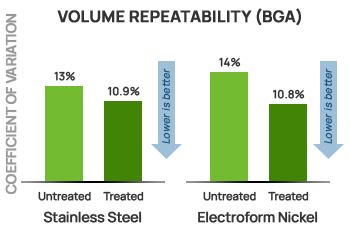

Better Volume Repeatability

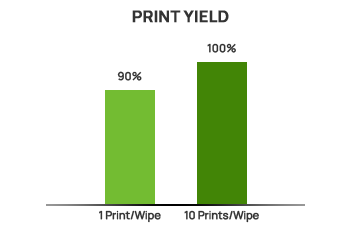

Reduce Under Wipe Frequency

Improved quality at 10X wipe interval

Improved quality at 10X wipe interval

1: “Fine Tuning The Stencil, Manufacturing Process and Other Stencil Printing Experiments”, Shea, C. and Whittier, R., Proceedings of SMTA International, October 2013l

Nanocoating & Nanoclear® Summary

- Increases print yields

- Reduces print volume variation

- Improves print definition

- Extends under wipe frequency

- Extensively tested & broadly adopted

- Decreases wipe consumables costs & downtime

- Delivers the industry’s best cost, performance and ease of use

Nanoproof™ PCB Waterproofing Summary:

- Liquid At Room Temperature

- Ability To Protect Many Substrates On A PCB

- Post Treatment Water Contact Angle From 100°-120°

- Post Treatment Oil Contact Angle Up To 76°

- Push Through Connectivity On Some Products

- Dry Time From 5-60 Minutes At Room Temperature

- No Cure Required & UV Tracer

ASET Corp.

ASET Corp.